Unlike centrifuge, distillation and Carl Fisher methods that do single point measurement at a time, a multi-channel scanning water analyzer (MCSWA) is a highly integrated apparatus for measuring water distribution, surface/interfacial levels and thicknesses of a multiphase dispersion continuously. The scanned curves provide water profiles and surface/interfacial information as a function of vertical position in respective testing samples. MCSWA is a proprietary technology developed by M & T Instruments Ltd. and is in patent pending status.

Working principle of the instrument

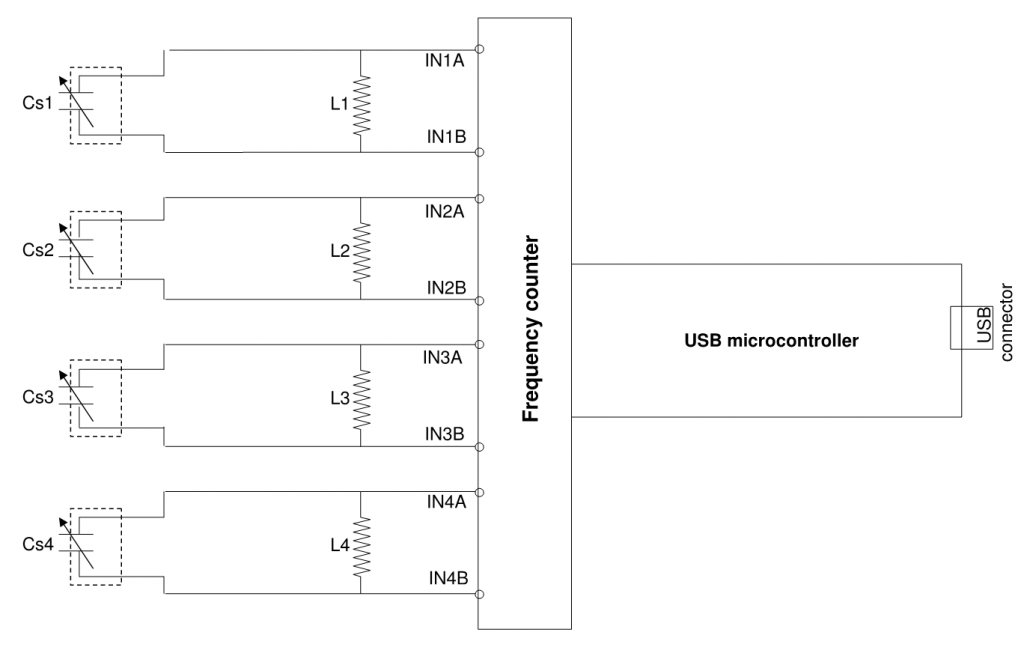

Fig. 1 is a schematic circuit of a data acquisition unit or printed circuit board (PCB) for a 4-channel scanning water analyzer. The data acquisition unit comprises 4 LC-tanks for connecting 4 capacitive sensors (Cs1, through Cs4), a high-precision frequency counter and a USB microcontroller.

Each LC tank has an inductor and a capacitor connected in parallel to form a resonance circuit. Its resonance frequency (F) can be expressed as

where L is the inductance of the inductor, Cs is the capacitance of a variable capacitor, which is actually the capacitive sensor. The resonance frequency is measured using a high-precision analog-to-digital frequency converter or counter. The measured frequency is then read by the USB microcontroller. The capacitance of a sensor (Cs ) can be calculated using

and its derivative as a function of bottle mark (x or sample volume) is

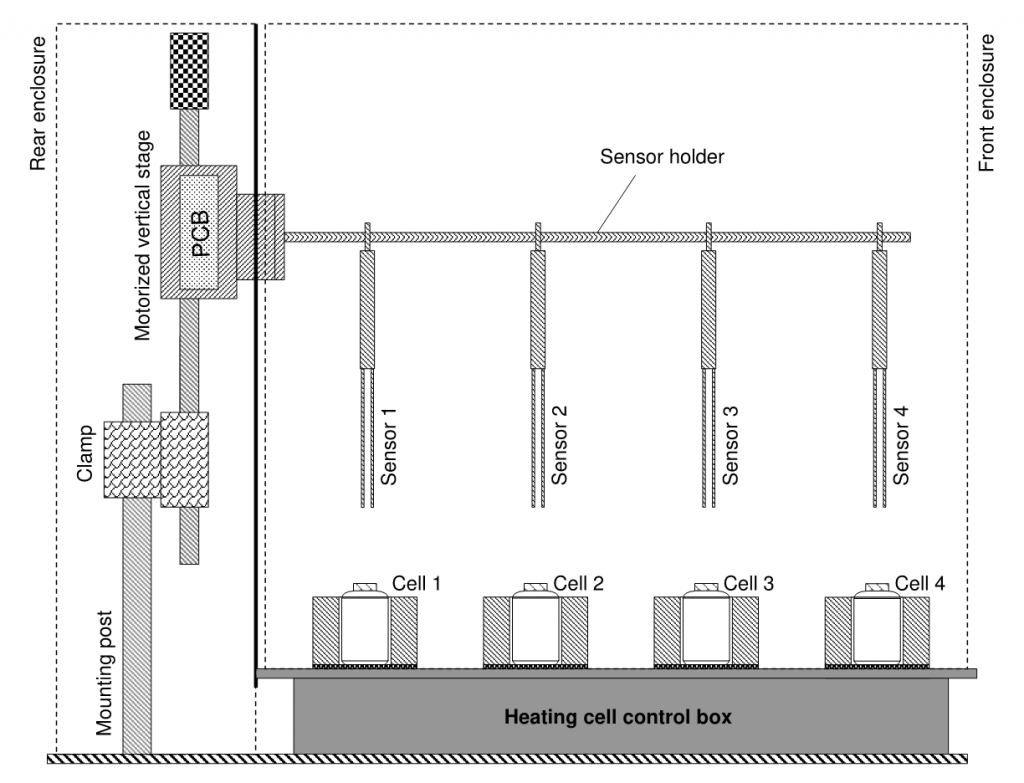

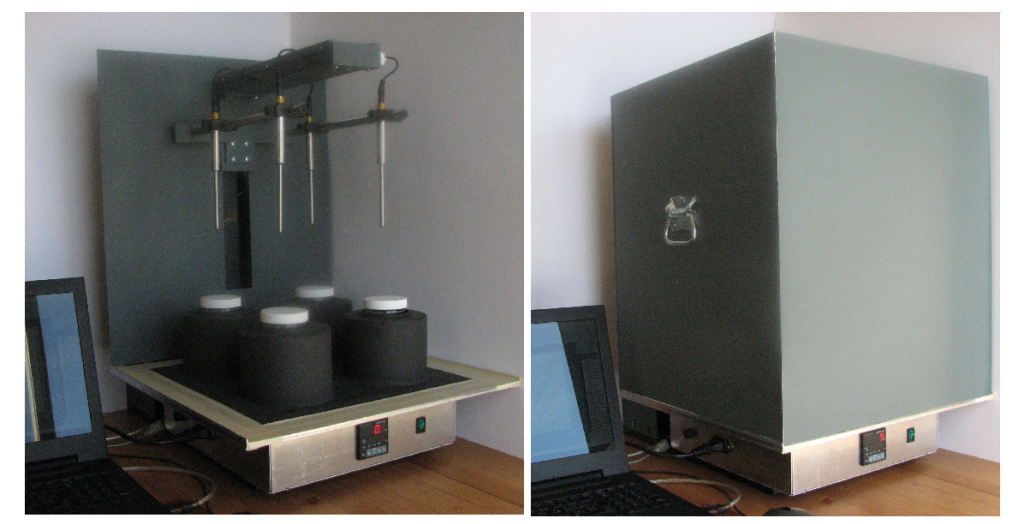

Fig. 2 is a schematic illustration of the 4-channel scanning water analyzer. It comprises a support station, a motorized vertical linear stage, a heating system having a heating cell control box and 4 heating cells, a sensor holder manifold holding 4 sensors, a data acquisition unit (or PCB) communicating between the sensors and a computer, a motorized front enclosure to close/open for loading samples and positioning sensors and a rear enclosure for electrical maintenance. The sensors can be well controlled to move down precisely to dip the sensors into the samples held in the 4 respective sample bottles, which are kept in the 4 heating cells maintaining a desired temperature. Four frequency curves and four capacitance curves are continuously acquired in a scan. Water distribution, surface/interfacial levels and thicknesses are derived via post-data processing. Both the scanning control and post-data processing are integrated into a user-friendly program using LabVIEW graphic interface. Fig. 3 is a photo of the 4-channel scanning water analyzer.

Features

- Simultaneously measure water distribution, interfacial levels and thicknesses,

- High-resolution water profile analysis, 0.1% by volume,

- Multiple sample scans and multiple phase scans simultaneously,

- Integrated program for scanning, data acquisition and post-data processing,

- No calibration is required for water content ranking for various chemical screening tests,

- Aqueous phase qualitative analysis,

- Scanned graphs and data can be exported to a clipboard, excel file and PDF file,

- Saved data can be reloaded for post-data processing,

- The heating cells can be operated up to 150 ℃ when sample bottles are capped, which can be used for sample conditioning to allow phase separation prior to scanning,

- Multiple channels (4 or 8) selectable,

- Suitable for both water-in-oil emulsion and oil-in-water emulsion systems

Specifications

- Name: 4-Channel scanning water analyzer

- Model: MCSWA-4-1000-1

- № of Channels: 4

- Water content resolution: 0.1% by volume

- Surface/interface level resolution: 0.1 mm

- Vertical stage velocity: ≤ 5 mm/s

- Vertical stage travel distance: 200 mm

- Scanning velocity: 0.100 – 0.125 mm/s

- Power supply for vertical stage motor: 24 V DC,

- Communication for vertical stage’s motor: USB to RS422

- Heating cell diameter: 63.5 mm for 200 ml glass bottles, 56.7 mm for 100 ml glass bottles

- Heating cell operating temperature: ≤ 95 ± 0.1℃, limited by water boiling point

- Power supply for heating cells: 85 – 240 V AC

- Front enclosure: Manual or motorized

- Dimension: W423 mm × D533 mm × H600 mm

- Computer included

- Operating system: Win 10

- CPU: ≥ 1.5GHz

- Memory: ≥ 8GB

- Hard disk: ≥ 500G

- № of USB 2.0 and/or 3.0 port: 3

- HDMI: 1